my67xr

Miniriders Legend and Master Spanner Spinning Mode

i thought i'd make a thread for Sand/Media Blasting.

you need a basic sand blaster kit, and a compressor (minimum 10 cfm), air line, sand, something like this-

You will need some good protective eye wear, safety glasses at the minimum, but you're best off using enclosed goggles, a hat and long sleeves.

i would advise you at least use a mouth/nose filter or respirator too.

the sand seems to get in everywhere, down your shirt, behind and in your ears etc, under your clothes too, and don't do it in your good clothes lol

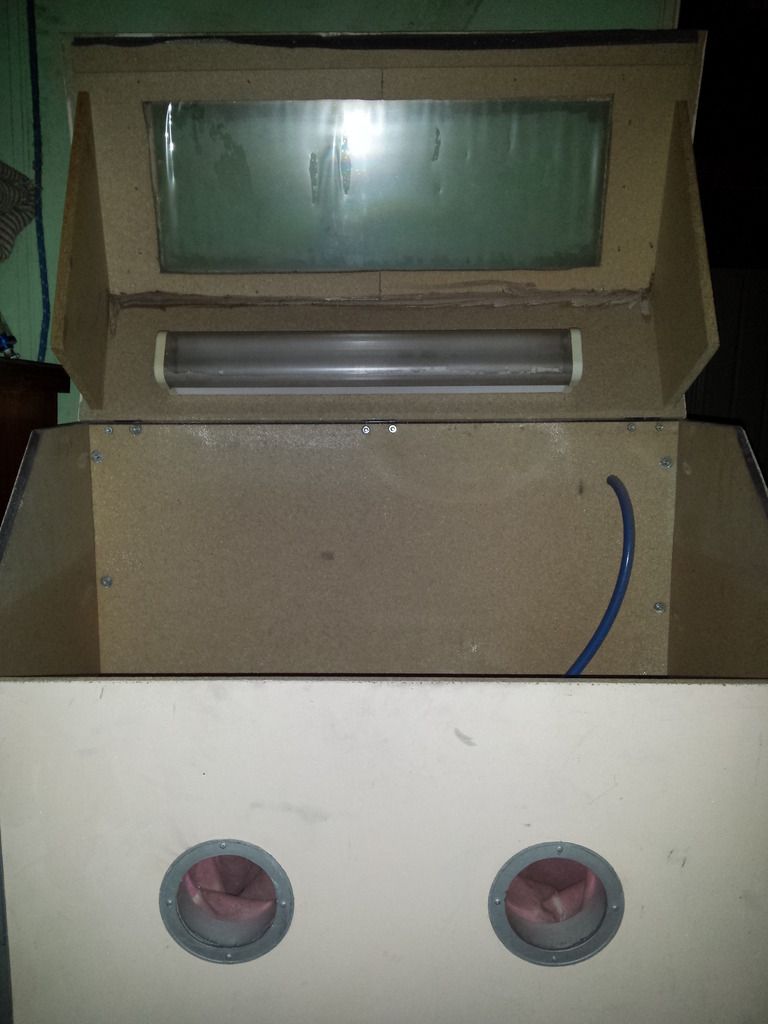

here is my cheap Sand Blaster i use at home, i picked it up on sale at Supercheap Auto a few years ago, cost me about $15 for the kit.

i found that the suction feed make's your compressor etc work a bit harder so i set mine up as a gravity feed.

i run the compressor at 110 psi.

i buy my sand at the local hardware shop, for $7 for a 20kg bag of dried building sand.

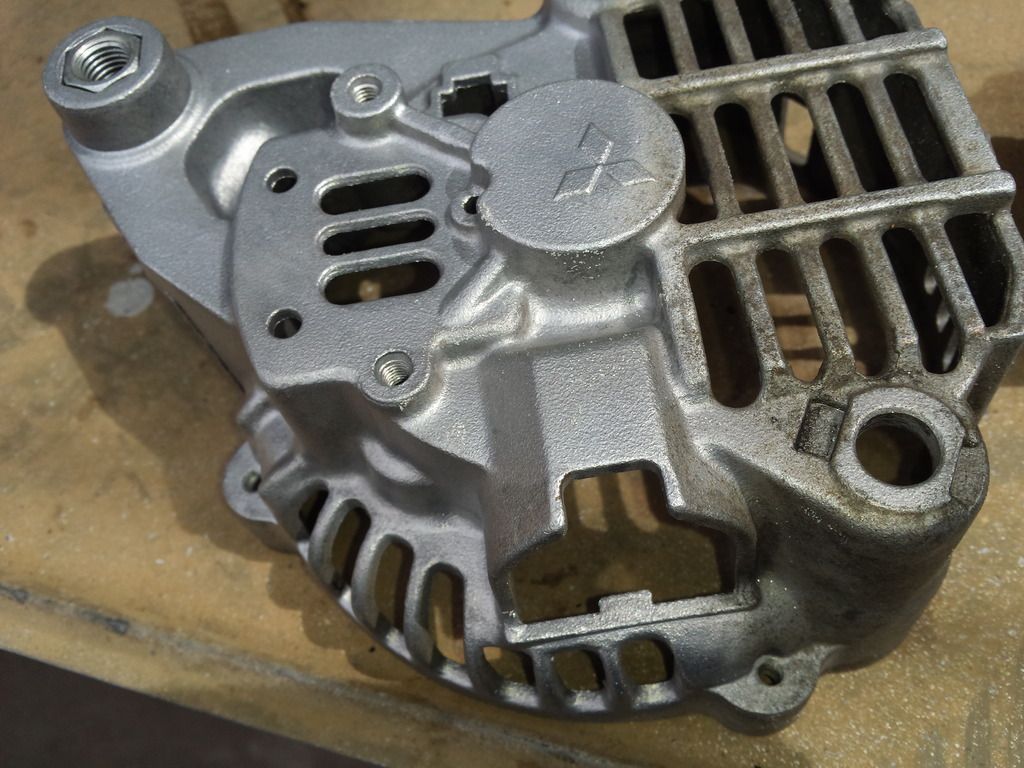

this is a exhaust manifold i wanted to clean up for a mates' Landcruiser on his 3F motor that i'm doing the head gasket on.

it has done 300,000 odd km's and has plenty of surface rust over it, and dried/caked on mud

here it is after a couple of minute's blasting, you can see the clean cast iron that's under the rust/mud

and a picture of the manifold after being finished, all painted up with 1050°C Exhaust paint ( high temperature)

the sand blasting really helps the paint to stick and stay on.

the fine pitting left after blasting gives the metal a greater surface area for the paint to bond to.

and here's a quick video of the process involved, click on it to view.

same video here on Youtube-

[video=youtube;sfSaz1AvD84]https://www.youtube.com/watch?v=sfSaz1AvD84&feature=youtu.be[/video]

you need a basic sand blaster kit, and a compressor (minimum 10 cfm), air line, sand, something like this-

You will need some good protective eye wear, safety glasses at the minimum, but you're best off using enclosed goggles, a hat and long sleeves.

i would advise you at least use a mouth/nose filter or respirator too.

the sand seems to get in everywhere, down your shirt, behind and in your ears etc, under your clothes too, and don't do it in your good clothes lol

here is my cheap Sand Blaster i use at home, i picked it up on sale at Supercheap Auto a few years ago, cost me about $15 for the kit.

i found that the suction feed make's your compressor etc work a bit harder so i set mine up as a gravity feed.

i run the compressor at 110 psi.

i buy my sand at the local hardware shop, for $7 for a 20kg bag of dried building sand.

this is a exhaust manifold i wanted to clean up for a mates' Landcruiser on his 3F motor that i'm doing the head gasket on.

it has done 300,000 odd km's and has plenty of surface rust over it, and dried/caked on mud

here it is after a couple of minute's blasting, you can see the clean cast iron that's under the rust/mud

and a picture of the manifold after being finished, all painted up with 1050°C Exhaust paint ( high temperature)

the sand blasting really helps the paint to stick and stay on.

the fine pitting left after blasting gives the metal a greater surface area for the paint to bond to.

and here's a quick video of the process involved, click on it to view.

same video here on Youtube-

[video=youtube;sfSaz1AvD84]https://www.youtube.com/watch?v=sfSaz1AvD84&feature=youtu.be[/video]

Last edited: