Cheer's Damian and Stu,

I think the home made bling came out really good, and only cost me a bit of time and a tin of paint.

A couple of quick video's to show how it sound's now.

I reckon the modified clutch spring's and shoe's work a lot better with this exhaust, the clutch start's to grab just as the powerband come's on.

[video=youtube;ZpmYGl5YPXs]https://www.youtube.com/watch?v=ZpmYGl5YPXs&feature=youtu.be[/video]

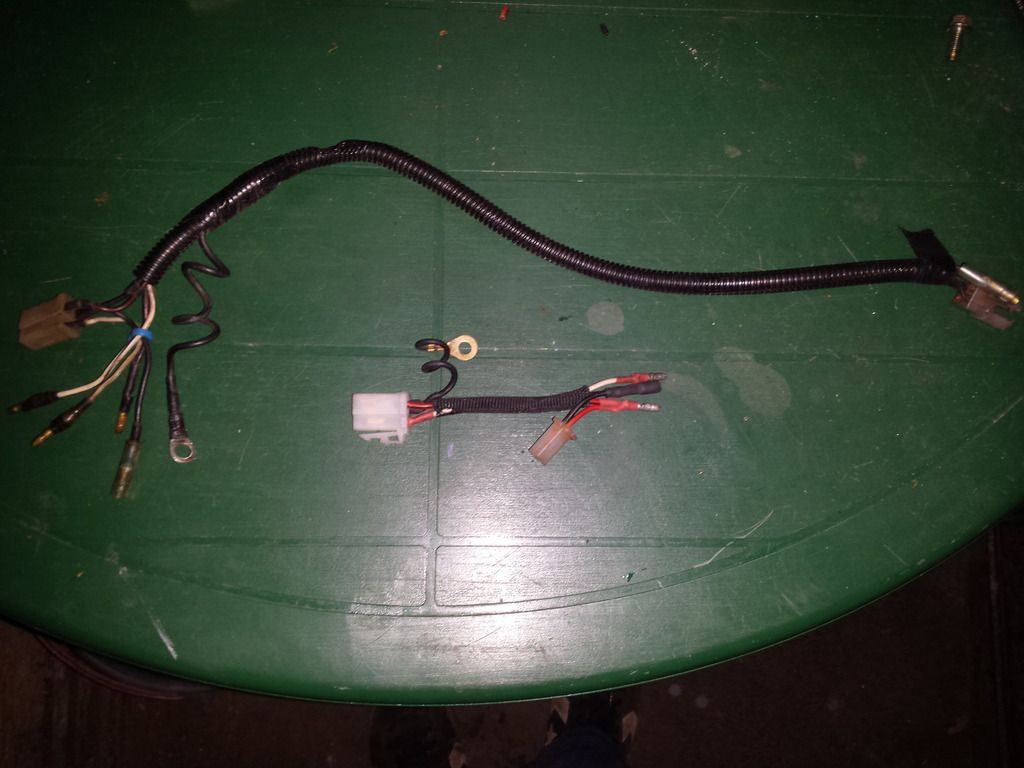

I thought using 2 part's off a KTM was a bit much (killswitch and exhaust), so i swapped the KTM style kill switch for a genuine Yamaha one.

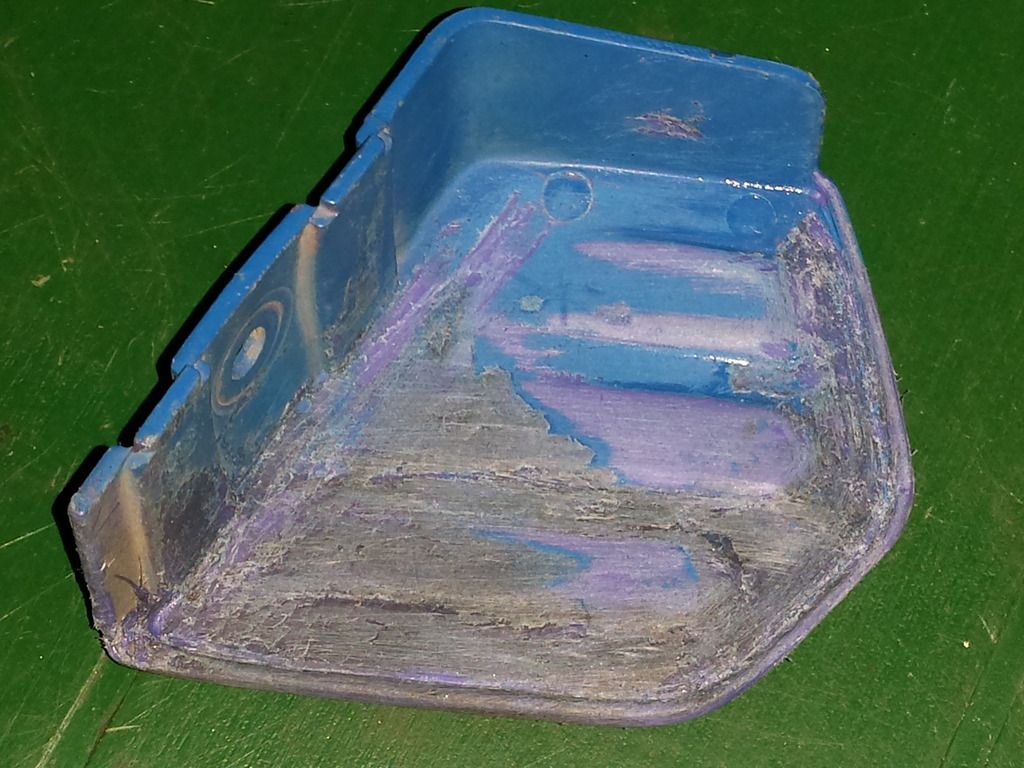

And i forgot to mention in that last post that i smoothed out the intake side of the carby, got rid of a ridge up the top, and rounded off the casting of the choke and pilot/main jet port's with a grinding burr, then some 180g sandpaper roll's in the die grinder before i blasted it, that should help out the flow

This is the front mounting face of the carby, i machined it back 1.5mm to allow the carby to sit onto the manifold pipe a bit more to help solve the vacuum leak problem

The dark bakelite sleeve is slotted so the carby can be clamped down onto it securing it to the manifold.

But it was fitted with the orientation of the slot's in the wrong place.

They should have been at 2, 4 8 and 10 o'clock so they won't let air in from the slot in the carby above it where the clamping bolt does up.

I also fitted new o'ring's to the mixture screw and idle speed screw while it was apart.

Standard carby intake side

PW / Suzuki FR70 carby after opening it up / smoothing it out.