mounting kit huh? only postie ive seen around here with a lifan he had the holes welded up and redrilled. hence my reasons for already having a c50 in the shed. no new mounts required!

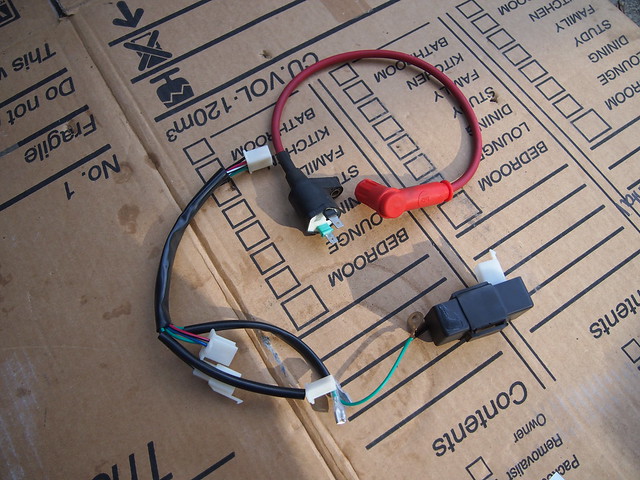

has it got a battery? and is it wired up properly, and the fuse is intact? and yep, check all the wiring, earths, etc. contact cleaner!

lights will flicker a little bit at idle but should be fine with some revs. a battery does help. but isnt necessary for running or rego. even try a few big 25v rated caps(30,000uF etc) tied in parallel. 16v will work but wont tolerate any spikes. 12v caps will result in large aluminium cans full of fluff and foil.

do NOT USE HID headlights on momo bikes with single headlights! whereas LEDs are brilliant for all auxillary lights

(whilst some will disagree) it seems the best "break-in" for longevity is to

a, warm up at a SLOW idle. heats the oil up, heats the metal up, heats everything up. always warm up!

b, when hot, THRASH IT! for a few minutes at a time. i always liked 3rd gear takeoffs, full throttle with some brakes for a km or two. then you can be a bit more gentle.

c, change the oil at least every 100km until it stops getting "sparkles".

d, ignore everything that says not to rev the motor for the first 1000km or so.

why? in the factory of, say, honda, when a bike is rolled off the line, some guy gets the delightful job of revving the things out to redline, and running up through the gears. under load. the final test. almost every single vehicle, car bike or truck, that is made to be sold, undergoes this "abuse".

single motors purchased seperately arent.

bearings dont "break in". plain bearings are supported by a film of oil under pressure. they NEVER touch unless the engine is having issues. ball bearings, even cheap chinese ones, are finished to the limit of commercially practical tolerances. they cant get any better or precise, and once again, all metal is seperated by a film of oil unless somethings gone wrong. like starting em up and flooring them straight away.

even the rockers on the cams are protected by this oil film. when thats broken through, things are really bad.

do it properly and you wont believe that oil can stay "golden" for 3000km or so... no ring blowby!

the rings, cylinder and gears are about the only parts that "break-in". the gears lose microscopic imperfections, giving the oil that glitter effect. the cylinder honing smooths down to small grooves and lands. grooves supply/retain oil, the lands provide the wear surface. the rings only get one chance to bed in properly before the hone marks lose their "sharp" edges. its why we (should) always replace rings and hone cylinders on tear downs. and never reuse rings except in an emergency!

noise? um... try finding the "hanger" pipes on the c50/70/90 and changing the header pipe to suit the 110. the tube from the back of a bus seat has just the right bend, the right diameter, the right length and is stainless to boot

you can grind the seams off the muffler section, remove or replace baffles, reweld and tada!

i used to just use lil straight through "bombs" on the bus seat header. loud but only for the people behind it!

theres software out there that does a good job at designing good silencers. theres more to it than a pipe with lots of holes drilled in it! less holes is better? wtf? but tis true.