I assume you are accusing us of doing both kick starting and bump starting wrong. Well, maybe, but I don't (yet) believe so...

I'll do anything to avoid reckless mechanical damage of any machine I own or am responsible for. Have done for as long as I can remember working on things. No one should need a special user guide or anything beyond some basic care and common sense to start a Lifan 140. But that's not the case. The engine (or at least some of them) does have a fault.

The kick in gear engines are based on a 110 cc Honda Nice engine that has a 49 mm stroke .... and probably runs about 9 to 1 compression ........

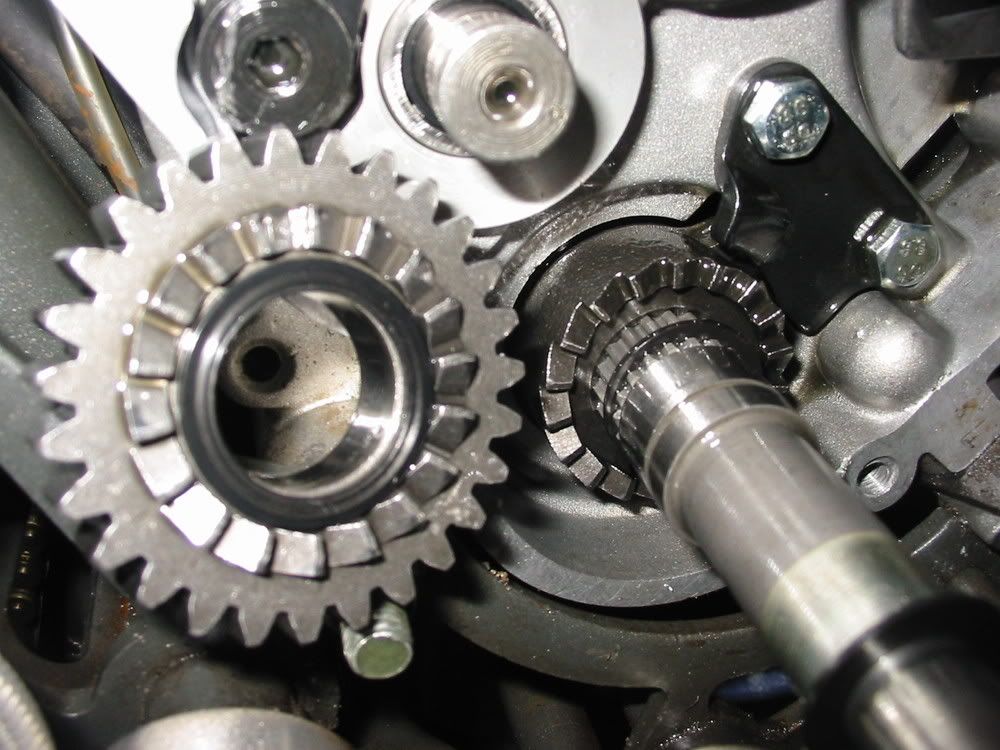

So here we have a chinese made version of the engine that has a 10 mm longer stroke and compresses 30 cc more .... EVEN a stock Nice engine would bust the kick start mech and gears or at the very least ... wear them out a lot quicker if modded to the same level .......

Honda XR100 engines also bust kick start gears when modded over 120 cc ..... just search Thumpertalk .......

You should have replaced the worn kicker gears when you fitted the other mods ..... and work out a replacement program based on your past knowledge of kicker gear life expectancy ...... just like how MX 4 strokes and 2 strokes need valve , piston and ring maintenance ...... it's got nothing to do with quality and everything to do with the fact that lightweight parts are being forced to do a heavy duty job ...... you have to be realistic .....

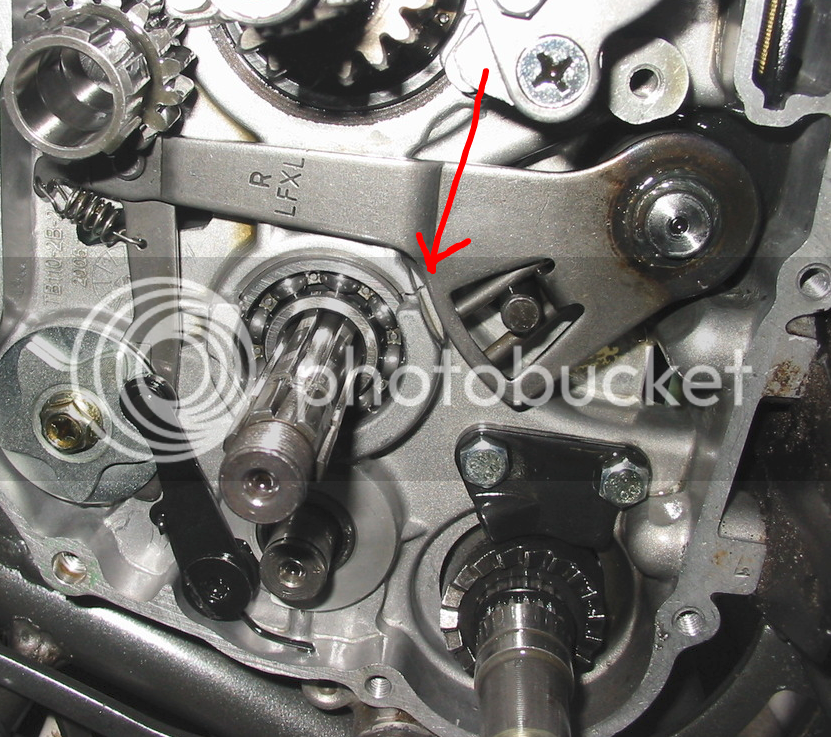

The "anti kick back" mech (NOT a decompressor) doesn't prevent kick back ...... it simply minimises the effect of kick back when it occurs by opening the exhaust valve to let some of the force of combustion pressure escape when the crank tries to go backwards ......

For people who expect too much and complain about a $300 engine ... I say get real , take your stock Lifan gears out and get an engineering firm to machine you up a super tough set ....... and be prepared to dig deep just so you can kick start your engine any old way and have it survive ......

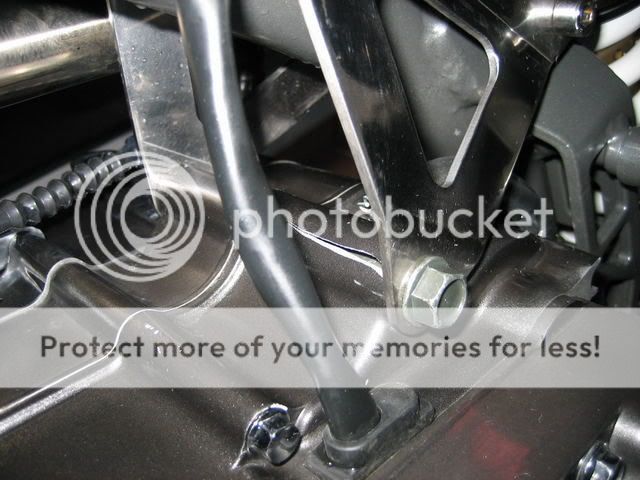

The flywheel /slinger weight WILL most definitely increase the force of kick back in the same way that it increases force to the rear wheel when the clutch is released ...... that's how it minimises stalling ..... What would you rather be shot with at close range if you had the choice ... a gun loaded with a styro foam headed bullet OR a copper or lead slug ?????? Weight creates inertia ........ and even a slight increase in weight can have a profound effect in certain situations .....

Also .... cam duration ALSO affects cranking compression .... I just neglected to add that fact since it has the exact same effect on compression that overlap has ...... overlap lets compression escape from the inlet and exhaust at the same time ..... and duration allows it to escape from the inlet valve at cranking speeds ..... IF your A1 cam allows your engine rev higher than stock ..... then it's definitely lowering the static compression ...... cams work by delaying the rpm that peak dynamic cylinder pressure peaks at ......

Kick back is caused by exploding fuel/air charge trapped in the cylinder ..... 2 other factors greatly influence its force and when it happens ..... compression and ignition spark ...... Eliminating one of the latter two from the equation can make a BIG difference ...... and since there is NO decompressor ..... the ONLY other alternative is to eliminate the SPARK .......

A sensible person (aka NON knuckle head) would hold their thumb on the kill button as they give their engine a good , fast and hard kick ...... THEN let their thumb off the kill button when the kick lever has passed the halfway point in its swing .......

Now there may be a few fools who have a problem with things I say (not you numroe) .... but they should simply smarten themselves up and get a life .......