Washed the bike today before a ride 2moz and noticed that where the bolt goes from one side of the frame threw the top of the engine to the other side of the frame there is like a bit of a crack on the left side where the bolt is going threw the engine casing !!!! Is there any fix for this because it looks like its apart of the whole engine case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

uh oh

- Thread starter scottlah

- Start date

Help Support Mini Dirt Bikes & Pit Bikes Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

If its cracked now, than its just gonna keep cracking pretty quick from now,

Considering that bolt takes all the weight from the footpegs,

Nothing you can do about it really, using metal putty will only fill the crack up, it wont make it bond together again to give the strength back,

wathc out it doesnt completely crack off and the engine falls down when you land

Than its engine replacement time!!!!

Considering that bolt takes all the weight from the footpegs,

Nothing you can do about it really, using metal putty will only fill the crack up, it wont make it bond together again to give the strength back,

wathc out it doesnt completely crack off and the engine falls down when you land

Than its engine replacement time!!!!

liljohn_92

Well-Known Member

get it tig welded

I_THUMP

Well-Known Member

As previously mentioned that is a problem that has no easy fix solution. It is now a hazzard waiting to happen and should not be ridden. You dont wanna be riding it when that snaps but if u do make sure u get it on video lol

I_THUMP

Well-Known Member

Get someone to video it coz if u knacker youself I wanna see it hahaha

wogtaz ryder

Well-Known Member

Get a cradlemount , or make your own

I_THUMP

Well-Known Member

This is a cradle mount frame, it has the motor mounted in three points. The cradle supports the motor from underneath.

This is the cradle mount below

This is the cradle mount below

Last edited:

Cactus Jack

Master Spanner Spinner

- Joined

- Jan 18, 2007

- Messages

- 2,742

- Reaction score

- 53

It can still happen in a cradle frame because the cradle (tensile steel) flexes downwards on landing from a jump .... that puts a sharp shock load on the top mount ...... the force is magnified IF the engine isn't bolted to the cradle first ... THEN the top mount plates bolted on with the holes lining up precisely so that the bolt slides in easily by pushing with your hand alone ...

IF the bolts have to be hammered or tapped thru then the top mount will be preloaded and guaranteed to crack ...... even 5 lbs of tension can be the straw that breaks the camel's back when added to the riders weight which increases via inertia of impact on landing ....

All other engines aside from Lifan 140 , 150 , the new Daytona 150 and YX 150/160 have crappy thin and weak top mounts that are designed only for road use ... ie Loncin , Ducar , Jialing GPX , YX140 , earlier model Lifans ........

Lifan 125 (grey) ,140 , 150 , the Lifan crank clutch 138's that come in a bike , and YX 150/160 have THICK engine mount lugs and some also use 8 mm bolts so as to keep the mounts thicker .....

You can fix cracked mounts easily by drilling them to fit a neat fitting steel sleeve ... then TIG welding the crack up ..... What cracks the cases is "hammering" from rutty tracks , bumps and jumps .... If you can keep all play to near zero ..... hammering can't occur ......

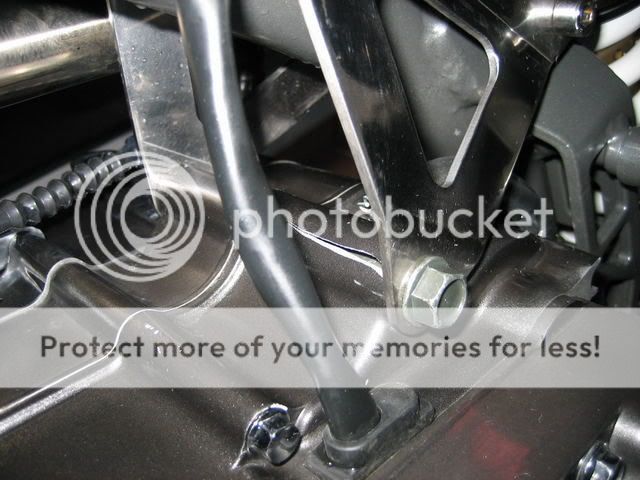

Here's a pic of a busted 125 Jialing GPX top mount in a Pitster cradle mount frame as proof that the "impossible" CAN happen despite what people may think .......

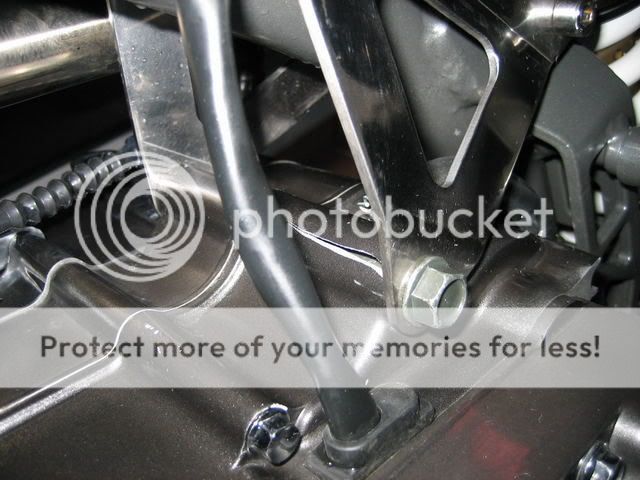

Pic of a Lifan "138" engine out of a non cradle DHZ bike showing the thicker mounts ...

IF the bolts have to be hammered or tapped thru then the top mount will be preloaded and guaranteed to crack ...... even 5 lbs of tension can be the straw that breaks the camel's back when added to the riders weight which increases via inertia of impact on landing ....

All other engines aside from Lifan 140 , 150 , the new Daytona 150 and YX 150/160 have crappy thin and weak top mounts that are designed only for road use ... ie Loncin , Ducar , Jialing GPX , YX140 , earlier model Lifans ........

Lifan 125 (grey) ,140 , 150 , the Lifan crank clutch 138's that come in a bike , and YX 150/160 have THICK engine mount lugs and some also use 8 mm bolts so as to keep the mounts thicker .....

You can fix cracked mounts easily by drilling them to fit a neat fitting steel sleeve ... then TIG welding the crack up ..... What cracks the cases is "hammering" from rutty tracks , bumps and jumps .... If you can keep all play to near zero ..... hammering can't occur ......

Here's a pic of a busted 125 Jialing GPX top mount in a Pitster cradle mount frame as proof that the "impossible" CAN happen despite what people may think .......

Pic of a Lifan "138" engine out of a non cradle DHZ bike showing the thicker mounts ...

Cactus Jack

Master Spanner Spinner

- Joined

- Jan 18, 2007

- Messages

- 2,742

- Reaction score

- 53

If you check in tormentandglory's 4 valve head thread , you'll see that he's had to weld repair a cracked top mount on the 110 ...... so he'd be able to give more detailed info on what's involved ....... and tell you if he thinks the repair job would be strong enough for off road riding .....