tassie01

Well-Known Member

- Joined

- Jan 22, 2008

- Messages

- 45

- Reaction score

- 1

The feelers have gone out for the Keihin FCR downdraft kit, I guess all I have to do now is wait a few days, and if no luck get on it again.

Ignition is sorted, small outer rotor stepping advance curve digital CDI, would use nothing else here.

Would have to say that they would be definately one of the best bugget upgrades you can get for pit engine, far an away better than any inner rotor kit.

As for the camshaft, well, still working on this, we all know that the best real way to get an engine to really go is to get a fast camshaft. For the 211cc 4v project, keen to use the stock cam, for now, I think. Got to remember that Mr Big 211cc probably will never see 10 000 rpm, and would probably suit the stock cam. Can have another made up later, if I dont see the big HP numbers.

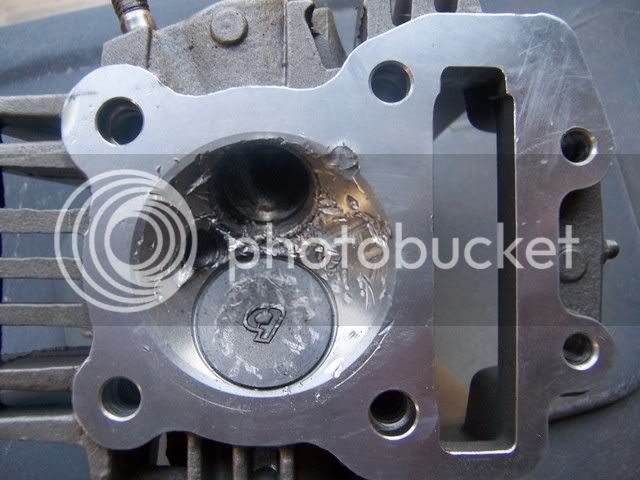

There are some pics of cams posted, lifan 150, takegawa R20, and the 4V YX, my fast cams are installed. Who can guess the donor bike for this experiment, see pics.

I have an old jailing 120 here, with an Akunar cam, a digi ignition, and a crappy lookin oval carb. It eats 140's for dinner. I can definately see the merit of a reprofiled cam.

Ignition is sorted, small outer rotor stepping advance curve digital CDI, would use nothing else here.

Would have to say that they would be definately one of the best bugget upgrades you can get for pit engine, far an away better than any inner rotor kit.

As for the camshaft, well, still working on this, we all know that the best real way to get an engine to really go is to get a fast camshaft. For the 211cc 4v project, keen to use the stock cam, for now, I think. Got to remember that Mr Big 211cc probably will never see 10 000 rpm, and would probably suit the stock cam. Can have another made up later, if I dont see the big HP numbers.

There are some pics of cams posted, lifan 150, takegawa R20, and the 4V YX, my fast cams are installed. Who can guess the donor bike for this experiment, see pics.

I have an old jailing 120 here, with an Akunar cam, a digi ignition, and a crappy lookin oval carb. It eats 140's for dinner. I can definately see the merit of a reprofiled cam.