Hi folks!

I'm currently working on my ZS155 engine (runnning a oko28 flatslide). Got a akunar cam (midrange) and HD valve spring set on its way. In the meantime I'm flowing/porting the head. Carb is set up pretty much spot on for current setup.

Now I thought the next thing to optimize would be igition and timing. I'm using the ZS' stock CDI and rotor kit and think I'll keep that. Or are there affordable CDIs with tuneable ignition courves? I guess no...

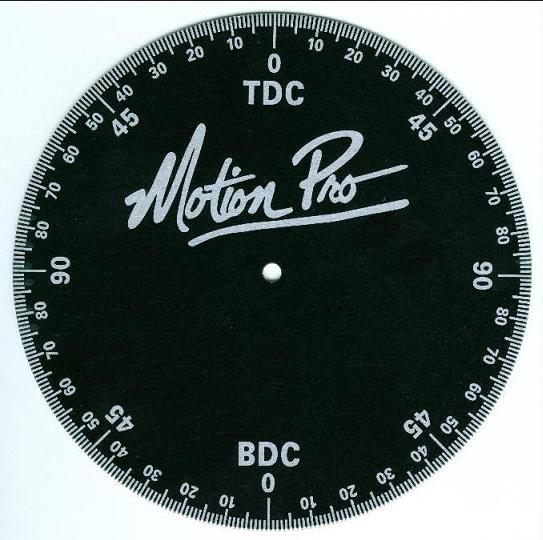

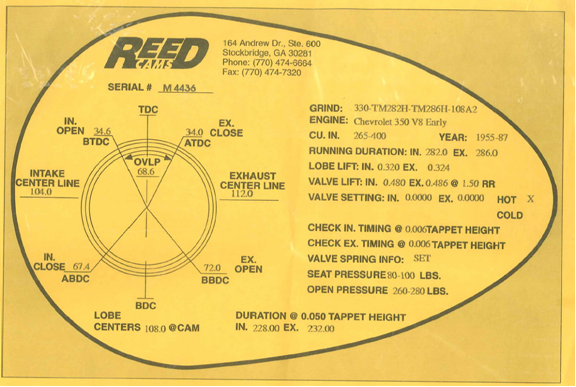

I however saw camshaft sprockets with 40degrees of adjustment to tune valve timing... this should help to control where the engine produces most power what cought my attention since I would be interested in generating most power in midrange...

Can anybody give me an understanding or guide (or link) of how to correctly tune valve timing? Would this even make sense without a dyno to check setup?

I heavent read much about that yet, it seems to be something of the more advanced tuning stuff I guess but I'm not afraid giving It a try.

I'm currently working on my ZS155 engine (runnning a oko28 flatslide). Got a akunar cam (midrange) and HD valve spring set on its way. In the meantime I'm flowing/porting the head. Carb is set up pretty much spot on for current setup.

Now I thought the next thing to optimize would be igition and timing. I'm using the ZS' stock CDI and rotor kit and think I'll keep that. Or are there affordable CDIs with tuneable ignition courves? I guess no...

I however saw camshaft sprockets with 40degrees of adjustment to tune valve timing... this should help to control where the engine produces most power what cought my attention since I would be interested in generating most power in midrange...

Can anybody give me an understanding or guide (or link) of how to correctly tune valve timing? Would this even make sense without a dyno to check setup?

I heavent read much about that yet, it seems to be something of the more advanced tuning stuff I guess but I'm not afraid giving It a try.