Barnesd09

Well-Known Member

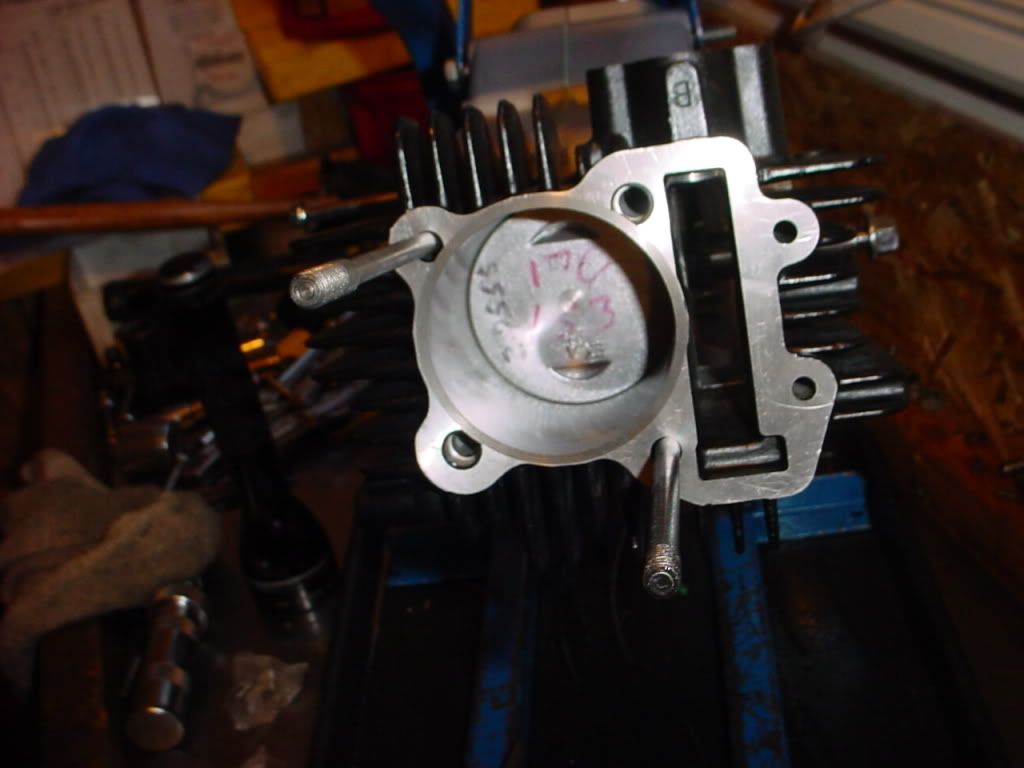

On the lookout for information about valve springs and everything else that goes with it that would be stable up to the range of about 17000 rpm, or if its even possible with a modified horizontal engine......

The older suzuki 250 across has a redline up at 16500 so I can't see why this can't be achive with one of our engines.

lol i being think about this a bit, and to better explain the importance of rod ratio and what effects it can have i'll use the ford V8 351C engine.. better known as a clevo

in standard form they wont play nice when applying massive cams to where the rpm range exceeds 6500.

now just buy using ford 302C rods (which are longer than 351C rods) and a piston with the piston pin higher up (closer to top) it allows them to rev much higher.. this also allows a shorter piston to be used which also reduces bore friction.. so its a win win in all accounts.

knife edging the crank and lightening everything where possible helps too.. but it could sacrifice a little torque in a smaller engine.. but then again rpm doesn't build torque so you have to chose what you want lol

Enter your email address to join: