storminnorman07

Well-Known Member

- Joined

- Jan 10, 2007

- Messages

- 159

- Reaction score

- 5

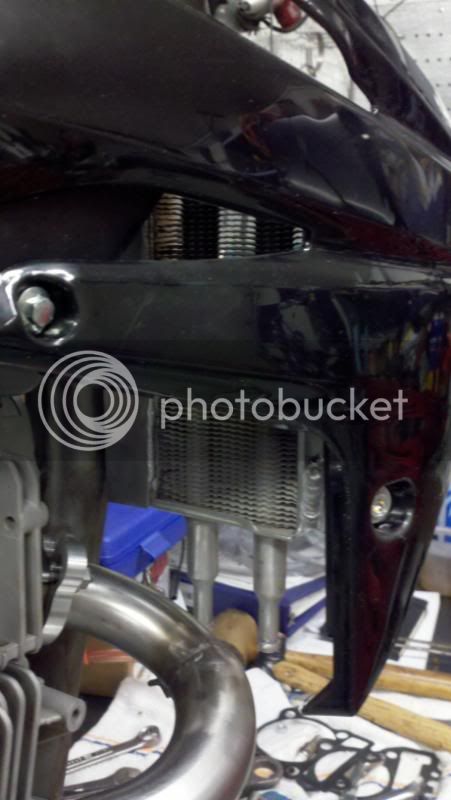

after all nice days we been having i decided it was time to get back after the mutant. would of got the motor completed tonight but ran into a uh oh. i was cutting notches in the piston went off the specs of the uncut piston and perfed it :-( oh well dumb mistake on my part. should have a new piston by wednesday if all goes right. then i can cut it down assemble it. then all is needed is i need to do a custom line to feed oil to the head and finish the backing plate. since i ran into the snag with the piston i start dry fitting everything on the frame to weld some tabs for the oil cooler and started prep work to make the cooler. with any luck it should be ready to go to p/c by end of week. fingers crossed.