Cordogs

Well-Known Member

Thought it was about time I documented one of my cheap China builds and put it on MR.

I've done a few of these in the past and got almost to the point of completion and thought, damn should of taken some photo's?

So here it is!

I've done a few of these in the past and got almost to the point of completion and thought, damn should of taken some photo's?

So here it is!

This poor neglected eBay special was rescued by a local bloke, who with some nail polish and a can of black spray paint turned it into the weapon pictured above ^^^

What's the nail polish used for you ask yourself?

Apparently it's and old trick small engine mechanics use to fix fuel leaks! who'd of known!

So first things first, I needed to work out what was salvageable and what wasn't. Turns out, not a lot! apart from the frame, foot pegs, chain guard and the seat. Everything else was rusted or perished. The front forks were like joined pogo sticks and the rear shock wouldn't even compress!! I could see the dollar signs starting to stack up pretty quickly, but "alas" I regress.

I always use the estimated sale price of the bike to be my budget. So for this little build I've set my budget for $400 including the initial bike sale cost. I new a rebuild for $300 was going to be a tall order, but I was confident so of I went to see the boys at Small wheels. They hooked me up with a brand new full exhaust, a brand new complete rear drum setup and new ignition lead for $65

Total build cost so far: $115

Already 1/3 of the way through my budget and none of the big ticket items brought I was in need of some freebies! So I rang around got a good mate of mine to sand blast the frame and swing arm and a few other bits n pieces and good old Brendo from here has kindly offered his Motovert forks and a set of pro tapers too! Winning

So at this stage of the build the bikes been pulled down, parts have been ordered and frame and bits have been sent away. Now its time for the clean up!

There's oil and black paint everything. So all bolts nuts and washers have been set a side for an acid bath, wire loom has been pulled apart with new connections added and cleaned, the chrome dome nuts on the engine head have had all the black paint rust removed and repolished, engine head has had an acid bath n scrub and has been repainted. The brake disc was in good order but in need of some paint also.

Also I decided to get out the polisher n clean up a few bits, here's a pic of my hi tech setup!

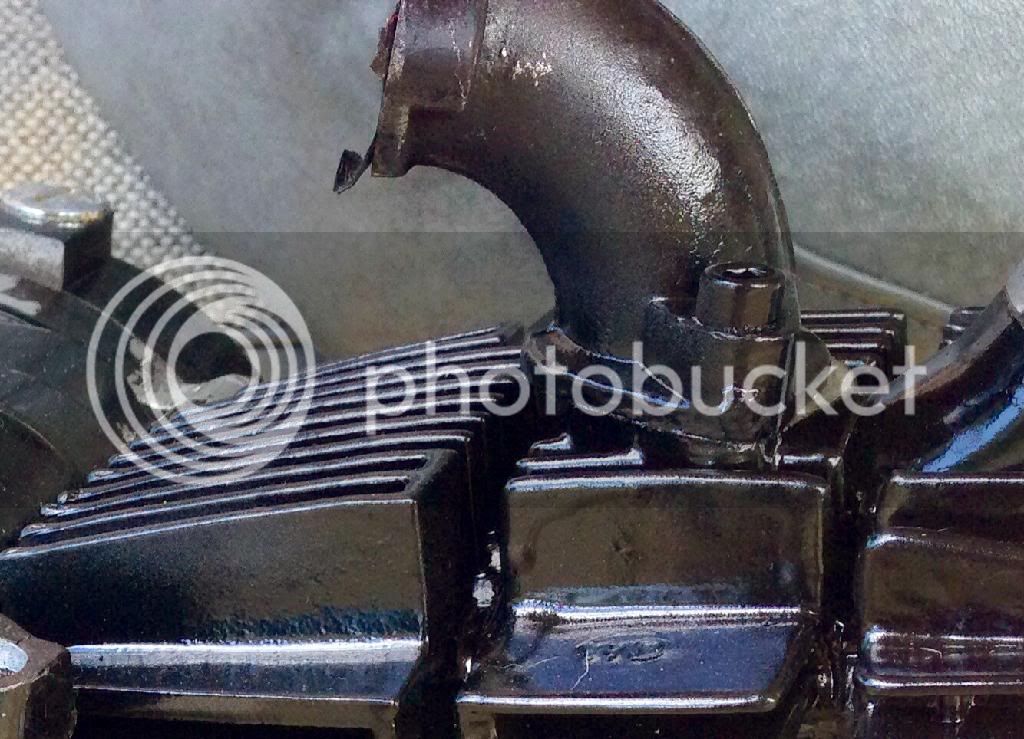

First up, that rude looking manifold!

So I sanded it up taking all the casting marks off.

Cut all the sanding out with the cutting sisle.

And finally polished out the cutting marks, instant bling!

Anyway that's as far as I've got so far! More photo's and info to come.

Last edited: