You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need help SSR125 problems

- Thread starter SSR-125

- Start date

Help Support Mini Dirt Bikes & Pit Bikes Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

my67xr

Miniriders Legend and Master Spanner Spinning Mode

ok then.

well the next thing to check is the gap between the pickup coil and the flywheel, (at the rear r/h side of the flywheel)

you need some feeler gauges,

turn the flywheel around by hand, until the little raised bump lines up with the centre of the pickup coil.

it should be as close as possible, without touching it, maybe .1mm (or .004") gap between the 2.

pics coming

well the next thing to check is the gap between the pickup coil and the flywheel, (at the rear r/h side of the flywheel)

you need some feeler gauges,

turn the flywheel around by hand, until the little raised bump lines up with the centre of the pickup coil.

it should be as close as possible, without touching it, maybe .1mm (or .004") gap between the 2.

pics coming

my67xr

Miniriders Legend and Master Spanner Spinning Mode

sorry my computer is slow, or photobucket is ?

here is the raised bump that you need to line up with the pickup

and the raised bump lined up with the centre metal tab/point of the pickup

this gap needs to be set to .004", if needs adjusting,

unscrew the 2 philips head screws and remove the pickup in or out to adjust the gap.

then retighten the 2 screws when you are happy.

btw have you checked the gap on the new spark plug too ? it should be .7mm, or .028"

here is the raised bump that you need to line up with the pickup

and the raised bump lined up with the centre metal tab/point of the pickup

this gap needs to be set to .004", if needs adjusting,

unscrew the 2 philips head screws and remove the pickup in or out to adjust the gap.

then retighten the 2 screws when you are happy.

btw have you checked the gap on the new spark plug too ? it should be .7mm, or .028"

my67xr

Miniriders Legend and Master Spanner Spinning Mode

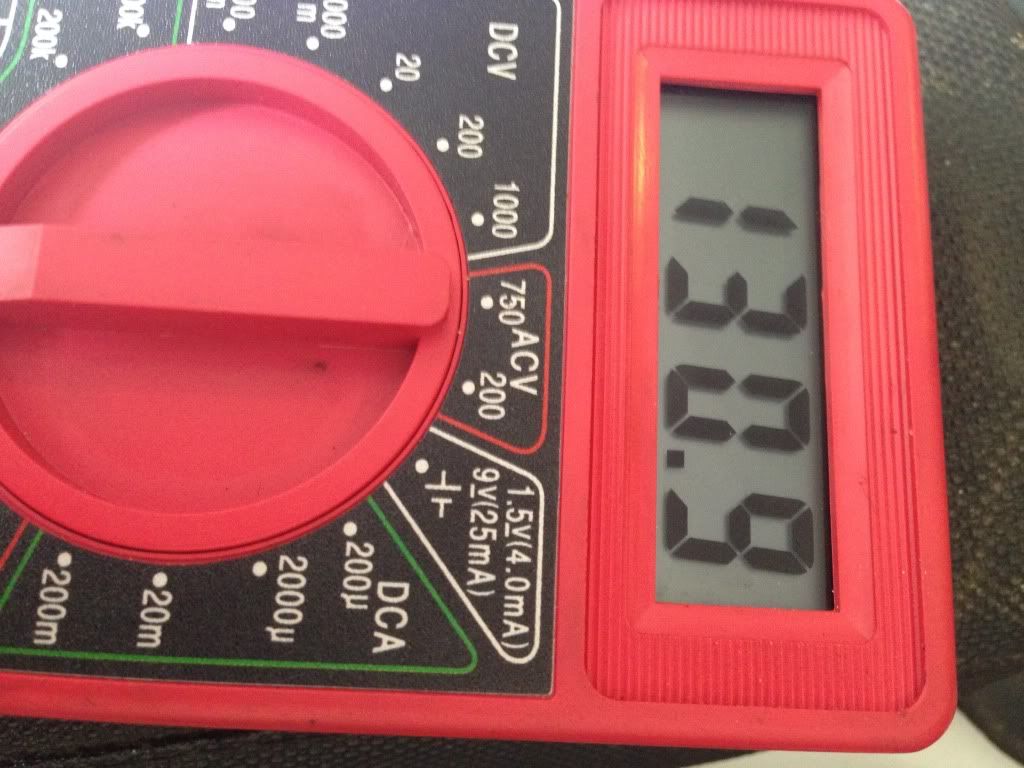

see if you can buy a cheap multimeter somewhere,

the $2 type shops here have them, under $10 usually.

then you can check if the stator is ok etc, they come in quite handy.

if you can buy/borrow one.

set it to 200 Ohms, put one test lead to the blue on the stator loom,

the other lead goes to green, (doesnt matter which way around the test leads are)

you should get a reading of 100-130 Ohms if it's ok

to test the source/charge coil, set the meter to 2000 Ohms

put one lead to the black w/red stripe, the other to green

you should get a reading somewhere around 360-380 Ohms

if during your testing either test comes up as 1, it could mean you have a bad connection on one test lead to the stator wiring.

or it may mean there is a broken wire somewhere too.

post up your readings after you have tested the stator

the $2 type shops here have them, under $10 usually.

then you can check if the stator is ok etc, they come in quite handy.

if you can buy/borrow one.

set it to 200 Ohms, put one test lead to the blue on the stator loom,

the other lead goes to green, (doesnt matter which way around the test leads are)

you should get a reading of 100-130 Ohms if it's ok

to test the source/charge coil, set the meter to 2000 Ohms

put one lead to the black w/red stripe, the other to green

you should get a reading somewhere around 360-380 Ohms

if during your testing either test comes up as 1, it could mean you have a bad connection on one test lead to the stator wiring.

or it may mean there is a broken wire somewhere too.

post up your readings after you have tested the stator

my67xr

Miniriders Legend and Master Spanner Spinning Mode

all good mate, let us know

SSR-125

Well-Known Member

- Joined

- May 18, 2012

- Messages

- 310

- Reaction score

- 3

i should probably go ahead and replace the stator cause it seems as if thats been my problem. i need a fly wheel puller so i dont mess anything up.. can i use my original fly wheel? i found 2 stators for my bike however one is more cheaper than the other.. is it the same part cause its $22 vs $30. i found the fly wheel puller as well which seems to be needed..

http://www.ebay.com/itm/FLYWHEEL-PU...Parts_Accessories&hash=item5aeb642509&vxp=mtr

http://www.ebay.com/itm/IGNITION-ST...Parts_Accessories&hash=item4ac5e4d572&vxp=mtr

http://www.ebay.com/itm/IGNITION-ST...Parts_Accessories&hash=item53d80b7eca&vxp=mtr

http://www.ebay.com/itm/FLYWHEEL-PU...Parts_Accessories&hash=item5aeb642509&vxp=mtr

http://www.ebay.com/itm/IGNITION-ST...Parts_Accessories&hash=item4ac5e4d572&vxp=mtr

http://www.ebay.com/itm/IGNITION-ST...Parts_Accessories&hash=item53d80b7eca&vxp=mtr

SSR-125

Well-Known Member

- Joined

- May 18, 2012

- Messages

- 310

- Reaction score

- 3

I ordered the fly wheel puller and the stator.. i thought even if its not bad its a step closer. i got a reading of 1 as i said before so i have a bad connection from the red black wire to the green.. do i need a different fly wheel? Do i need anything else other than the fly wheel puller? does it come off and go back on a certain way? never done this before so any help would be awesome!

my67xr

Miniriders Legend and Master Spanner Spinning Mode

did you set the multimeter to 2000 ohms? to test the source coil in the stator

it is possible that the wire from the stators' coil is broken too?

if you have the new one ordered,

then try cutting the black/red striped wire back an inch shorter and test it again, keep shortening it and retesting.

you might get lucky and cut off enough to be able to find continuity before the break, then hook it up to the cdi wire at that end.

you have nothing to lose.

your flywheel will be fine to reuse with the new stator.

the flywheel has a cast iron boss riveted into the middle of it, that fits over the crank.

there is a cutout/slot in the boss, that lines up with the keyway on the crankshaft.

they can only fit on one way.

it is possible that the wire from the stators' coil is broken too?

if you have the new one ordered,

then try cutting the black/red striped wire back an inch shorter and test it again, keep shortening it and retesting.

you might get lucky and cut off enough to be able to find continuity before the break, then hook it up to the cdi wire at that end.

you have nothing to lose.

your flywheel will be fine to reuse with the new stator.

the flywheel has a cast iron boss riveted into the middle of it, that fits over the crank.

there is a cutout/slot in the boss, that lines up with the keyway on the crankshaft.

they can only fit on one way.

SSR-125

Well-Known Member

- Joined

- May 18, 2012

- Messages

- 310

- Reaction score

- 3

the multimeter was set to 2000 ohms and still got that reading of 1.. and i made sure that it was green to the red/black. does it sound right to be my stator? or do you think its the other wires? So as of now i should shorten the red/black wire that is coming from the stator? or the red / black wire coming from the coil/ cdi part?

my67xr

Miniriders Legend and Master Spanner Spinning Mode

you only tested the black w/red stripe coming from the stator didnt you?

you need to get a reading for it to charge up the cdi so it is ready to fire.

shorten the black w/red stripe coming up from the stator,

you might find the wire has broken an inch or 2 down from where it plugs in to your loom ?

retest it each time you shorten it, strip back a bit of the insulation of the end of the wire

you need to get a reading for it to charge up the cdi so it is ready to fire.

shorten the black w/red stripe coming up from the stator,

you might find the wire has broken an inch or 2 down from where it plugs in to your loom ?

retest it each time you shorten it, strip back a bit of the insulation of the end of the wire

my67xr

Miniriders Legend and Master Spanner Spinning Mode

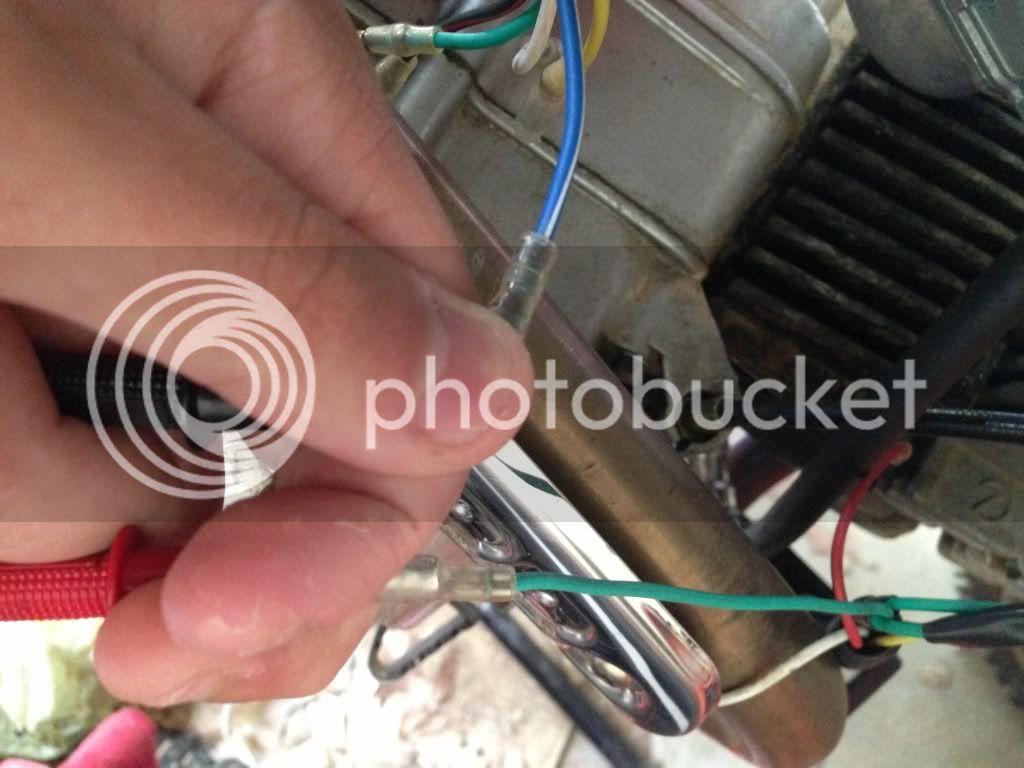

in your pic in post #190 when you are testing the wiring,

you should have the lead that goes to the green, on the green from the stator.

but, by getting a reading from the blue w/white stripe it shows that the engine is earthed well.

i'm off to bed, i'll read your results in the morning

good luck.

you should have the lead that goes to the green, on the green from the stator.

but, by getting a reading from the blue w/white stripe it shows that the engine is earthed well.

i'm off to bed, i'll read your results in the morning

good luck.

SSR-125

Well-Known Member

- Joined

- May 18, 2012

- Messages

- 310

- Reaction score

- 3

i am sorry for you to keep having to explain everything to me lol but im trying! what i did was shortened the red/black wire from the stator.. put it to 2000 ohms on the multimeter and took one connection from the multimeter and put it to the shortened one (black/red) that i cut and the other connection i put to the green wire that was not off the stator.. and got a reading of 1.. where did i exactly go wrong?

my67xr

Miniriders Legend and Master Spanner Spinning Mode

one wire to the black w/red, the other wire to the green from the stator

trim the wire back an inch, then test it,

if you don't get a reading then trim it again and test it.

still no reading trim it back again, etc etc etc

if you end up cutting the wire back right down to the case and still find no reading,

it doesn't really matter, as you have a new Stator unit and flywheel puller on it's way anyway.

if the lighting coil is faulty it will most likely show up as having a high or low resistance (high or low ohms reading)

for you to be getting no reading at all, then there must be a brealk in the black wire /w/red stripe.

trim the wire back an inch, then test it,

if you don't get a reading then trim it again and test it.

still no reading trim it back again, etc etc etc

if you end up cutting the wire back right down to the case and still find no reading,

it doesn't really matter, as you have a new Stator unit and flywheel puller on it's way anyway.

if the lighting coil is faulty it will most likely show up as having a high or low resistance (high or low ohms reading)

for you to be getting no reading at all, then there must be a brealk in the black wire /w/red stripe.

SSR-125

Well-Known Member

- Joined

- May 18, 2012

- Messages

- 310

- Reaction score

- 3

I have trimmed down that black/red wire and kept going cause i have a new one that will be here in 2 days anyways and still have that reading of 1.. i think that the black/red wire has a poor connection or is loose or something because that's the only thing that would make sense. The flywheel puller should be here tomorrow and the stator I'm expecting earthier tomorrow but probably Monday. i will keep you updated! Having a reading of 1 and having that poor reading can lead to a bad stator and have the bike not start? I'm wondering if this has been my problem cause i have replaced everything else.. (coil,plug,wire,) the only thing that is left is the harness off the coil which has the wires that plug into the stator wires. What do you think? I appreciate you helping me out Craig, its a great help!

my67xr

Miniriders Legend and Master Spanner Spinning Mode

if you are not getting a reading from the black w/red stripe and green, then the cdi is not getting power to charge up ready to send the the ignition coil.

normally when the stator goes, it will start to play up when hot etc.

they wont usually work one minute then wont start the next, but there is a slim chance.

how much extra is it to replace the main wiring loom, they sell for about $10 here in Aust.

if they are only cheap, it might be worth replacing that too, then you know it all should be good for quite a while.

normally when the stator goes, it will start to play up when hot etc.

they wont usually work one minute then wont start the next, but there is a slim chance.

how much extra is it to replace the main wiring loom, they sell for about $10 here in Aust.

if they are only cheap, it might be worth replacing that too, then you know it all should be good for quite a while.