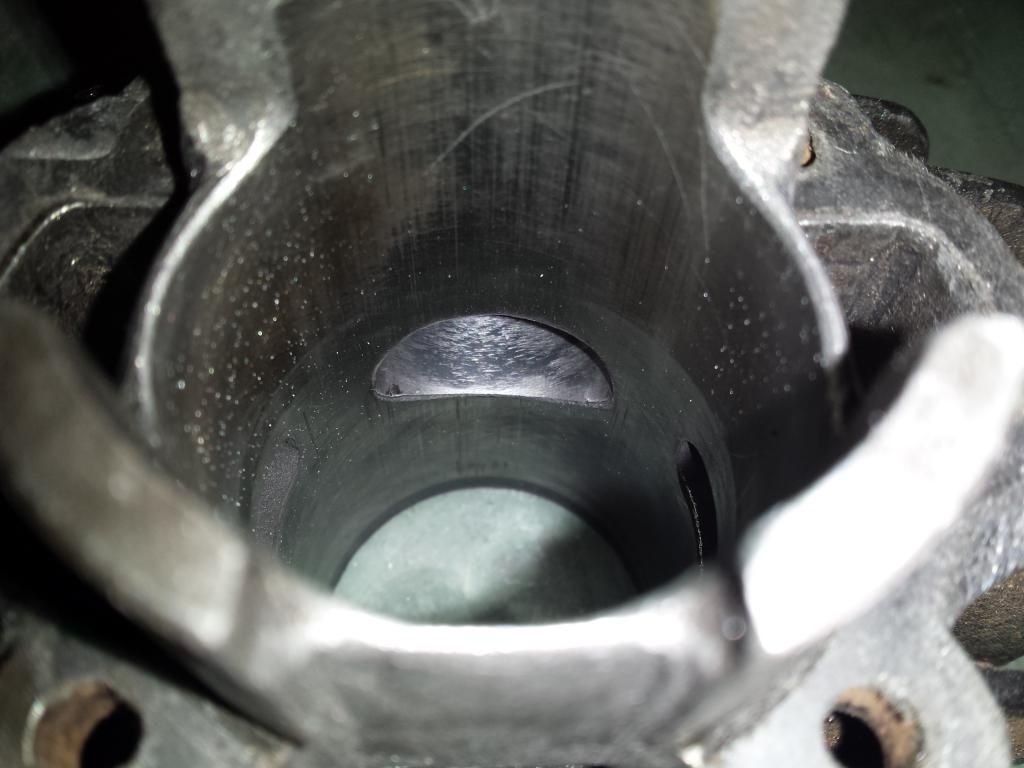

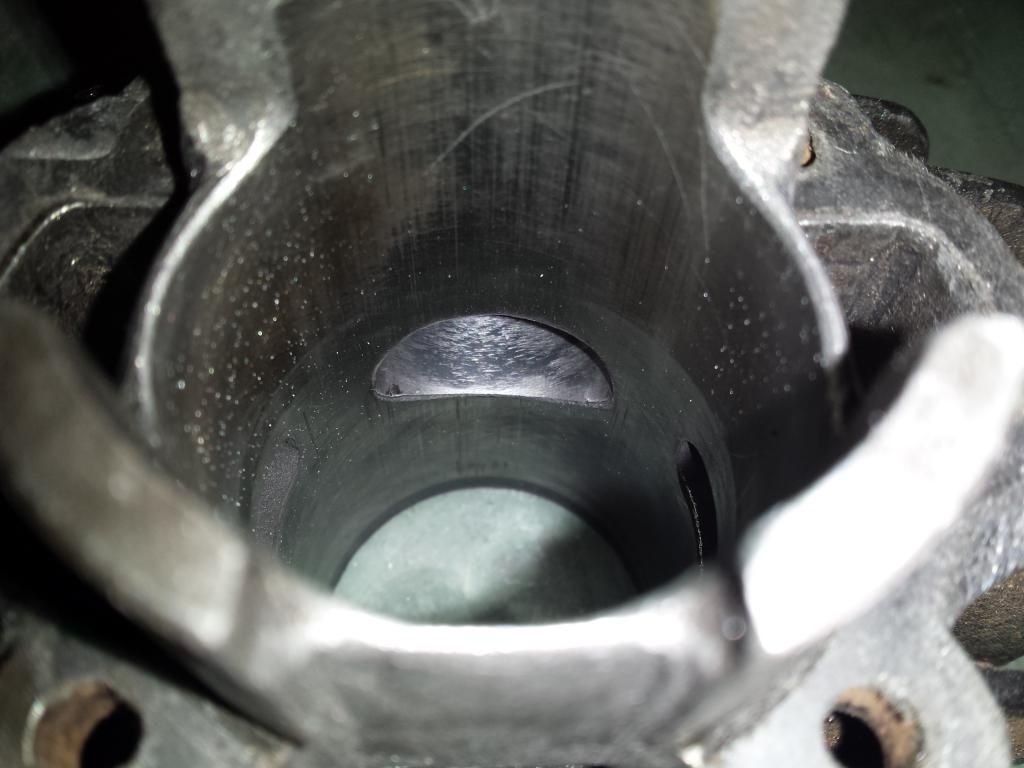

today i thought i'd check the piston/bore with the way it was running.

it all looked ok, just a it rich so i gave it a clean up/out.

thought i might do a bit of porting/polishing while it was apart.

i opened up the top of the exhaust port and widened it about 2mm, this will help the gases escape easier

i also semi knife edged the transfer ports, and the intake port to help it flow better

and cut back the short returns a little as the ports enter the cylinder.

when i refit the cylinder i will use 2 base gaskets to lift the exhaust port and give it more flow

the standard PW50's piston sits 3.5mm up past the bottom of the exhaust port.

and i also cleaned up the head inside and out.

the flat silver i used when i sprayed it the first time stained easily, and was hard to clean.

so i rubbed it back and resprayed it with a silver base, and a couple of coats of clear engine enamel to seal it all.

and i repolished the combustion chamber as i didn't spend much time doing it the first time, and i had left a few scratches